Major Benefits of Rapid Prototyping for Automotive Industry

To maintain and increase competitiveness, manufacturers seek to deliver their products to businesses as quickly as possible. The best way to achieve this goal is by hiring and generating Rapid Prototyping Services. It is an essential phase of development, is a somewhat tedious process: to know which solution will be the best. There is a long design and refinement phase with a few iterations.

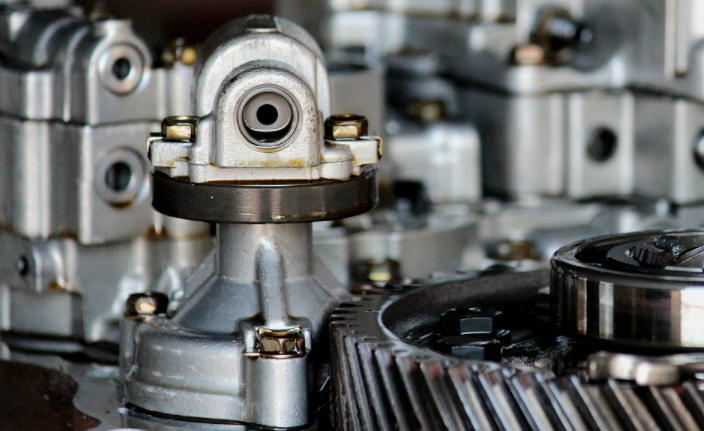

Rapid prototyping can be used to create visual variants that serve to visualize the idea of a solution and provide a way to evaluate and improve the design and working prototypes that can speed up reverse engineering and the creation of discontinuous components. Here are some reasons why this alternative is considered the best for auto parts manufacturing.

Increases the Production Speed Significantly

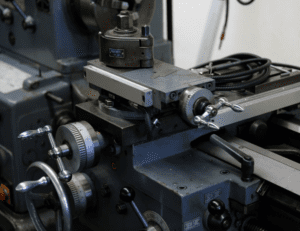

Rapid prototyping is considered an ideal option for the rapid production of various automotive parts. The technologies used in this particular process, such as 3D printing, play an important role in reducing the immediate time to create specific things. Customization is very easy because only one controller is required for your 3D CAD design model.

This is different from traditional options where you may have to spend a lot of time setting up machines. The drawings needed for this particular process can be created in a short period, even in a single day. Companies looking for 3D parts can set up their orders and have them ready in a couple of days. The rapid manufacturing discovered in rapid prototyping has caused the number of vehicles produced each year to reach record numbers.

Elevates the Quality and Accuracy of the Parts Production

Rapid prototyping in the automotive industry is considered necessary for the production of high-quality automotive parts. Numerous elements that make up an automobile must undergo various tests to prove their safety in use. The best thing about rapid design is that superior quality car parts can be produced in a short time. The accuracy is also quite high when it comes to making car parts through rapid prototyping. There is no need to remember to make changes to these items regularly.

Rapid prototyping in the automotive industry is considered necessary for the production of high-quality automotive parts. Numerous elements that make up an automobile must undergo various tests to prove their safety in use. The best thing about rapid design is that superior quality car parts can be produced in a short time. The accuracy is also quite high when it comes to making car parts through rapid prototyping. There is no need to remember to make changes to these items regularly.

Spends Less to Earn More

You will most likely invest less in the rapid prototyping of car parts. First of all, the human labor required is minimal, so you don’t have to worry about labor costs. There is no need to spend a lot of money on new materials and many other things included in this option for prototyping auto parts, which is usually common when using traditional alternatives. Almost all processes related to rapid prototyping are automated, so you can spend money on different jobs. This makes it an ideal and affordable option for creating auto parts.

Choosing the best rapid prototyping company is very important to get high-quality parts. One of the things you need to think about is whether the design company you want to choose has the latest technology. New and advanced technologies are being introduced every day. Companies that use the latest rapid prototyping technologies will guarantee you high-quality car parts. This is something to pay close attention to. Also, you need to consider the production rates of a particular car prototyping company. This is crucial to ensure that you get more parts in a short period. Keeping these very important features in mind will allow you to acquire the best parts from the rapid prototyping company of your choice.…